RESEARCH NEWS

RESEARCH NEWS

The blood line

Published: 27 November 2019

Researchers from the Interdisciplinary Laboratory of Physics have determined a scaling law for the transversal drift of red blood cells in blood vessels.

Voice in sight!

Published: 04 December 2018

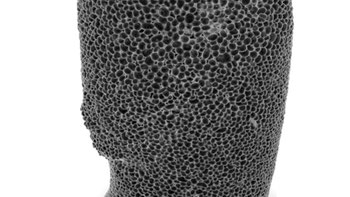

Researchers from the Laboratoire 3SR and their colleagues have released the first 3D high-resolution images of the human vocal folds thanks to X-ray microtomography coupled with a phase retrieval technique.

The amazing coils of the entangled wire

Published: 17 October 2017

Researchers from Laboratoire 3SR and their colleagues from ILM (Lyon) have designed a new material consisting in a single long coiled elastic or super elastic wire.

Grafting antibiotics on cellulose for a new generation of strictly contact-active antimicrobial materials

Published: 11 October 2016

Researchers form the Laboratory for Pulp and Paper Sciences and their colleagues have achieved the first chemical grafting of penicillin directly on the surface of micro-fibrillated cellulose films.

Liquid micro-motors: the power of non-muscular cells

Published: 06 July 2016

By coupling experimental and numerical approaches, researchers from the Laboratory for Interdisciplinary Physics have elucidated the mechanisms by which a cell adapts its shape to a substrate's stiffness.

Low intensity ultrasound treatment for high efficiency milk filtration

Published: 22 September 2015

The researchers from the Laboratoire de Rhéologie and their collaborators have demonstrated the efficiency of ultrasound to avoid membrane fouling during tangential ultrafiltration of skimmed milk.

Grain of snow, or no grain of snow?

Published: 07 April 2015

By coupling experimental observations and mechanical modelling, researchers from INRAE Grenoble have developed a new computational method to simplify the identification of individual snow grains.

Light control of swimming algae: new perspectives for bioprocesses

Published: 27 November 2014

By studying the behaviour of swimming microalgae, the researchers from the laboratory LIPhy have highlighted an interesting photo focusing phenomenon that could serve some applications.

Undulations, waves, drops: from the virtual to the real

Published: 07 April 2014

Researchers from the laboratory LEGI and their colleagues from the Virtual Assisted Atomisation Consortium have taken a big step towards the simulation of the complex flow instabilities.

Four dimensional characterisation of sand deformation

Published: 11 June 2013

For the first time, the researchers from the 3SR lab were able to observe the motion of fifty thousand sand particles in 3D using x-ray micro-tomography.

3D X-ray imaging of biofilm deposition

Published: 09 January 2013

Researchers from the Laboratoire 3SR have obtained the first 3D images of a biofilm, formed on a fixed bed of biolite beads.