Experimental investigation and modelling of gas-liquid-solid reactors

Post-doc project

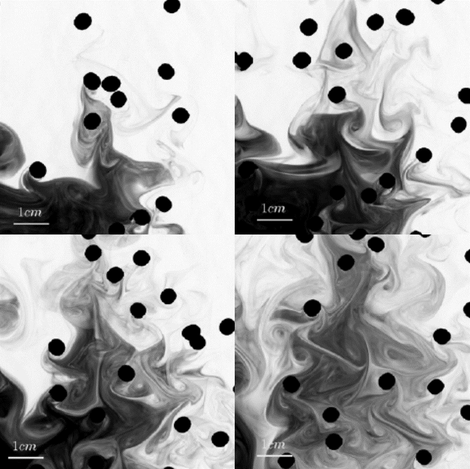

Gas-liquid solid reactors are widely used for chemical process such as petro-chemistry, water treatment or bio-processes. They usually consist in a large vessel at the bottom of which bubbles are injected. Solids particles are commonly added as extra-chemical components or catalysts to favor chemical reactions. The advantages of bubble column reactors relies on the large interfacial area densities due to the presence of bubbles, and on the good mixing properties brought by the dynamics of the bubbles without using mobile mechanical parts. Although the range of industrial applications is really broad, it remains difficult to predict the time for a chemical component or a catalyst particle to be transported and/or mixed by the flow. Such a prediction is mainly limited by the lack of phenomenological models concerning dispersive properties in three-phase (solid / liquid / gas) reactors. The construction of such models would not only require a deeper knowledge of the hydrodynamics properties of the flow, but also a more precise characterization of the local dispersion of particles within the flow. Today, none of the existing time-resolved experimental device is able to locally measure the solid fraction of particles in a gas-solid-liquid reactor.

The objective of this project is thus twofold:

Firstly, the hydrodynamic properties of three-phase reactors is investigated more in depth thanks to recent advances and new measuring techniques developed by the partner laboratories, giving

access to bubble size and bubble velocity in complex bubbly column flows.

Secondly, a new time-resolved and local measurement of the solid fraction within the flow is developed, combining the fluorescence technique brought by the PI of the project (former researcher at

the LGC Toulouse), with optical velocity probes developed by the A2PS company in Grenoble. The objective here is to map the dispersion of solid particles in the reactor. Such sensors are tested

and validated under controlled experimental conditions, before being applied to more complex configurations.

Combining the development of new local measurements and well-known experimental situations, the project aims at proposing new phenomenological models for particle dispersion in complex gas-solid-liquid flows.

CONTACTS

- PI: Elise Almeras

- Co-PI: Martin Obligado and Davide Beneventi

- Post-doc: Elise Almeras

PARTNERS

- Laboratory for Chemical Engineering (LGC, Toulouse, France)

- LEGI

- LGP2

FUNDING

Tec21