PHOTORHEO - Stress-induced bioluminescence as a stress sensor in complex fluids

Post-doc project

In this project, we propose to visualize and measure elongation and shear stresses in low Reynolds (Re) flows of complex fluids by means of stress induced bioluminescence of microalga Gonyaulax Lingulodinium Polyedrum (LP).

Indeed, the existing stress measurement techniques are always indirect: a proxy such as strain or displacement is measured, from which stresses are subsequently interpreted. If a constitutive law between stress and strain law is lacking (which is usually the case for complex fluids) these techniques cannot be used. We strongly believe that our project will help to elaborate a direct measure of stress in any kind of complex material once bioluminescence induced by shear and extensional stress will be calibrated on a simple fluid.

Thanks to a previous financing, we now master the right conditions for growth of LP and we can control properly the biological system for doing Physics. We have characterized the motility and the coupling of motility and luminescence. We are well equipped now to continue this project as follows:

- Set up a four-roll mill device to characterize the luminescence versus elongation stress. In the literature, a lot of studies have been achieved to measure shear induced bioluminescence of LP in a simple fluid but in order to characterize stress in complex fluids (like polymer solution for example), bioluminescence response to extensional stress is important. Therefore, we want to calibrate LP bioluminescence induced by extensional stress of a simple fluid.

- Polymer solutions and colloidal gels will be used to alter the flow curve and tune the rheological behavior in terms of viscosity and elasticity. The stress map will then be drawn from luminescence measurements. We chose these two different kinds of complex materials to test this new method of stress measurement.

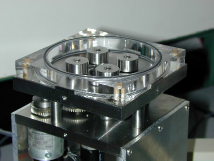

Figure caption: The four-roll mill device consists of a watertight and temperature-controlled internal cylindrical cell (diameter 96 mm) enclosing four rollers sets at the corners of a square. The dimensions and distance between the rollers were optimized to obtain the best approximation for homogeneous extensional flows. The rollers are turned at the same speed in opposite directions thanks to specific gearings and motors equipped with tachymeters, in order to apply an extensional flow at the center of the four roll mill. The cell is composed of a reservoir of transparent Plexiglas and stainless steel thermal control top and bottom plates, which enclose the suspension. The top and bottom parts were designed with quartz glass windows at their center, in order to observe the streamlines and the bioluminescence emitted under extensional flow at the center of the four-roll mill.

CONTACTS

- PI: Salima Rafaï

- Co-PI: Frédéric Pignon

- Post-doc: Monica Bravo Anaya

PARTNERS

- LIPhy

- LRP

FUNDING

Tec21