Improving Nanocellulose Gels, Films and Foams through Crosslinking and Responsive Behavior

Short term visitor's project

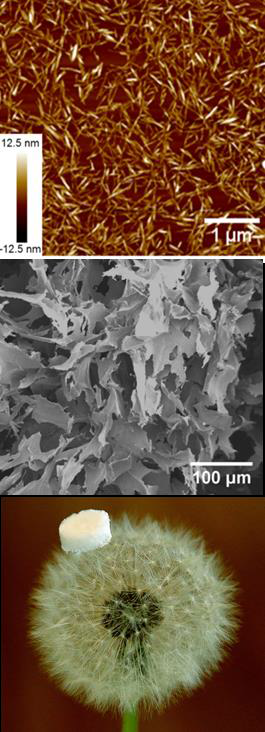

Nanomaterials have great potential for a vast range of applications including medicine, electronics, biomaterials and energy storage/production. A promising family of renewable nanomaterials is nanocellulose, in the form of nanofibrillated cellulose (NFC), cellulose nanocrystals (CNCs), and bacterial cellulose (BC). These natural polysaccharide nanoparticles can be obtained from cellulose - the most abundant form of biomass in nature. With advantages over inorganic nanoparticles such as low cost, biocompatibility, biodegradability, good mechanical properties and chemically reactive surface functionality, nanocellulose has great potential for use in scaffolds for tissue engineering, coatings, polymer composites, absorbents/adsorbents, and biodegradable food packaging, to name just a few.

Due to the high specific strength and modulus of crystalline cellulose, both CNCs and NFC have been used mainly as nano-fillers to reinforce different polymer matrices. Two major challenges in developing new materials based on nanocelluloses include (1) tuning the interactions between nanocellulose and the matrices and (2) achieving uniform/controlled distribution of nanocellulose in the material. These are both significant because they will largely determine the mechanical performance of the final materials.

But aside from mixing nanocellulose into polymer matrices, CNCs, NFC and BC on their own can also be assembled into films, gels or foams in a controlled manner resulting in unique properties. While previous work has most often focused on physical interactions between nanocellulose our recent results indicate that chemical crosslinking of CNCs leads to more robust materials with structural integrity in both wet and dry environments. This crosslinking has greatly extended the potential applications and processing methods for CNCs but remains to be fully exploited.

The originality of this project is to build on biocompatible functionalization routes based on chemical crosslinking, specifically with the aim to produce interconnected (crosslinked) networks of nanocellulose with enhanced performance.

This work will be the first aimed to combine crosslinking and responsiveness in nanocellulose-based products using non-toxic chemical modifications allowing for materials that are suitable for biomedical, food, cosmetic and pharmaceutical applications.

CONTACTS

- PI: Emily Cranston (visitor)

- Co-PI: Julien Bras

PARTNERS

- Sustainable Nano-Biocomposites Group, Department of Chemical Engineering (McMaster University, Canada)

- LGP2

FUNDING

Tec21