CAVITOSE: Use of Cavitation to produce cellulose nanofibrils and simultaneously its functional suspension

PhD project

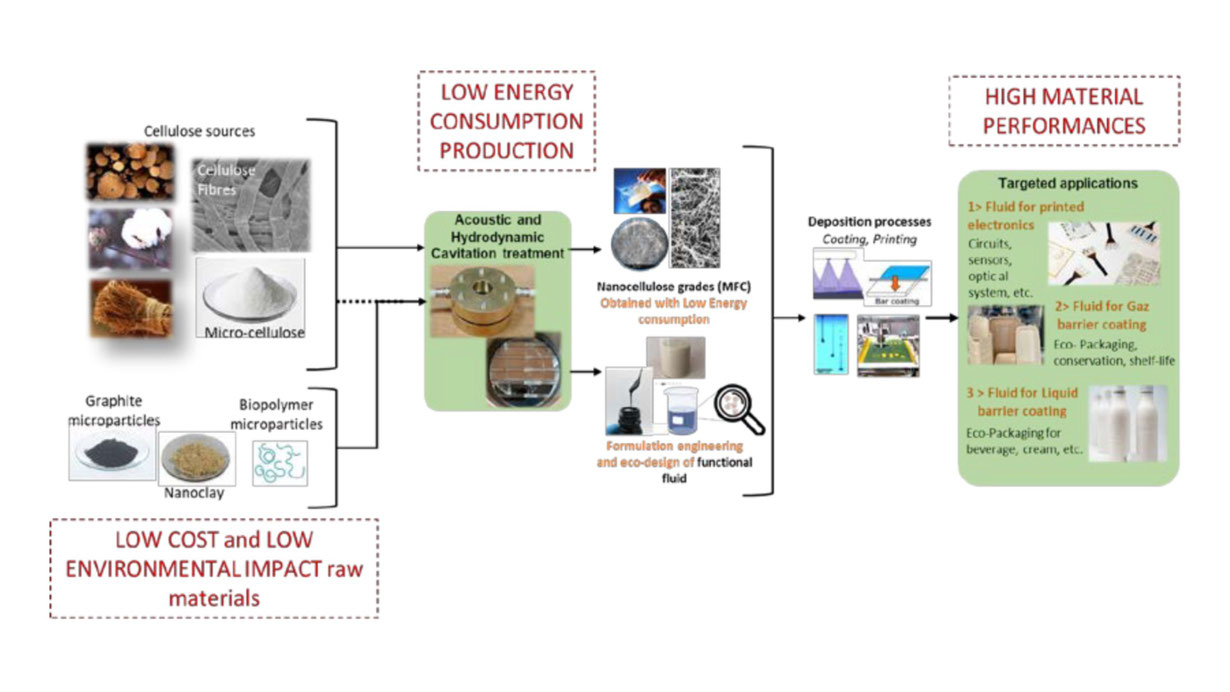

Cellulose nanofibrils (CNF) are considered as promising eco-friendly materials to support the current societal demand of plastic substitution. This project aims to explore a newcompetitive process that would overcome, from technological and economical points of view, the conventional ones which are used up to now and that are based on high shear rates homogenizers. The idea is to use hydrodynamic cavitation "on a chip", that is inside microchannels as amicrofluidic advanced cavitating process.

Hydrodynamic cavitation (HC) takes advantage of both high shear rates and shock waves induced by bubbles collapses, that help for top-down exfoliation of layered materials. HC "on a chip" combines the advantages of HC but without damaging materials under exfoliation during the multi-passes process, with a low energy consumption.

The first part of the project is to replicate for cellulose what has been successfully performed and patented for graphite, considering the distinctive properties of cellulose suspensions monitored under moderate pressure drops through submillimeter gaps.

The second step of the proposal is evenmore challenging and ambitious, because it aims to combine simultaneously in a same hydrodynamic process, the exfoliation of cellulose and graphite microparticles, in order to directly obtain a suspension free of any surfactant, where graphene nanoplatelets would be dispersed into a CNF network.

When succeeding, and then expanded to nanoclay or bio-nanoparticles, this breakthrough will open large opportunities for the development of conductive inks, gas barrier coatings, or liquid barrier films.

FUNDING

Tec 21