Additive Manufacturing of Bioinspired Orthopedic Casts

Short term visitor project

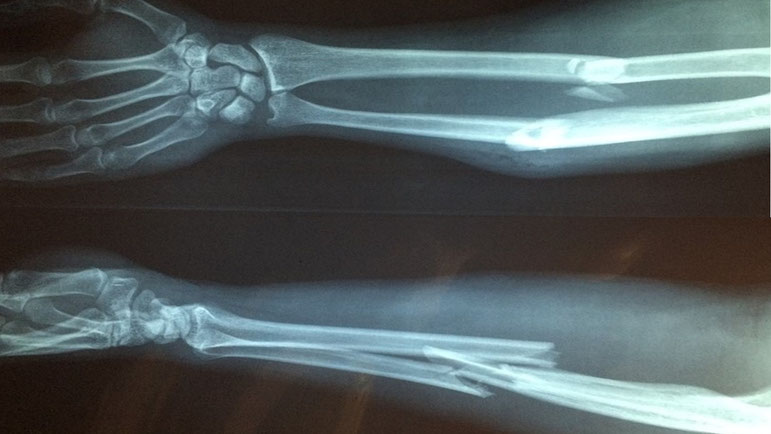

Once a bone fracture has been stabilized, it can be treated with an orthopedic cast. Conventional plaster casts, while effective in relieving pain, are limited in their ability to improve patients' quality of life by restoring mobility, reducing fatigue, and minimizing disruption to their daily routines. The possibilities for individualized medical devices, such as the orthopedic cast, are expanding rapidly thanks to the development of three-dimensional printing as a powerful tool in the rehabilitation industry.

However, there is still a lack of versatility and durability in 3D-printable materials. To improve the mechanical performance of Stereolithography SLA (Stereolithography) 3D printing, this work creates bio-based resin/cellulose nanofibre composites as an alternative material that might be used to make 3D-printed cast. To generate specimens, the fabricated cellulose nanofibres will be placed into a resin 3D printer. International criteria will be used to assess mechanical performance (Figure 1).

The Charpy Toughness and Vickers micro hardness of all tested materials will be determined. Microscopic and surface investigations on broken tensile specimens will be performed using scanning electron microscopy and atomic force microscopy. Thermal gravimetric analysis, differential calorimetry, and dynamic mechanical analysis will be utilised to investigate the thermal and thermomechanical properties. The appropriate and optimal concentrations of orthopedic cast nanocomposites will also be determined.

This project involves a collaboration between the LGP2 and the Mechanical Engineering Department of the Arab Academy for Science and Technology (AASTMT) in Egypt.

PARTNERS

Mechanical Engineering Department of the Arab Academy for Science and Technology (AASTMT), Egypt

FUNDING

Tec 21