HIGH-TECH LABCOURSES

HIGH-TECH

LABCOURSES

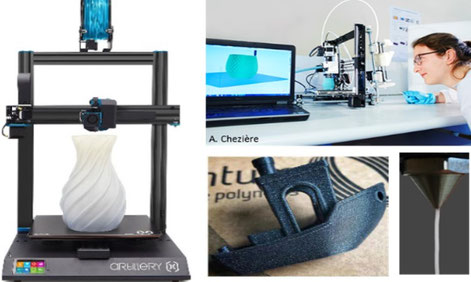

Exploring additive deposition

This practical module introduces participants to the principles and use of 2D / 3D additive manufacturing processes. Additive manufacturing can be broadly categorized into 2D and 3D processes that build fully volumetric components directly from digital models. While 2D techniques such as inkjet printing or thin-film deposition typically produce layers only a few micrometers thick, 3D methods can achieve layer heights ranging from hundreds of micrometers to several millimeters—or even centimeters—depending on the process. Both approaches face challenges in material development, compatibility, process control, and dimensional accuracy. In this session, we will examine these processes, compare their capabilities, and discuss the key factors influencing final part quality.

PREREQUISITE

This lab-course is well suited to M1 and M2 students having a background in materials and process engineering

DESCRIPTION

From Inkjet to 3D additive manufacturing

Two deposition techniques will be explored: inkjet printing (2D) and extrusion-based 3D printing (3D). The objective of the session is to identify the critical parameters of each system and understand their impact on the printed layer deposition quality. This includes considering the physicochemical properties of the fluids, the key process parameters, and the surface and interface characteristics. For inkjet printing, the focus will be on the mechanisms of picoliter-scale droplet generation whereas or 3D extrusion printing, attention will be given to quality criteria and process control. Application examples in the field of functional printing—including printed electronics, biomedical applications, and luminescent materials—will also be presented.