Valorisation of recycled starch, a new concept of biorefinery in paper recycling process

Post-doc project

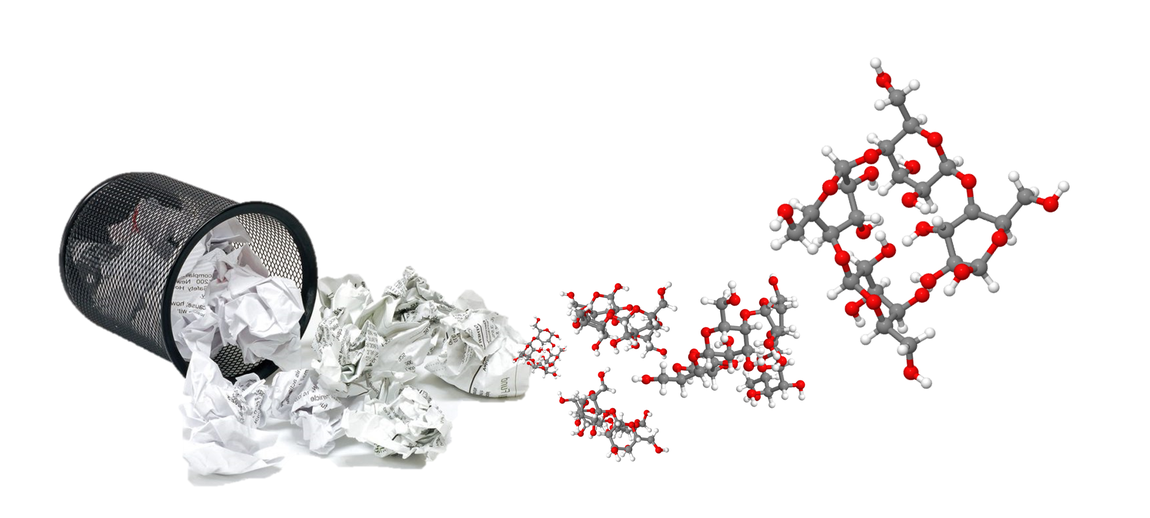

Recycled papers and boards (old corrugated containers) contain a significant amount of starch, which usually represents an issue during recycling, as it accumulates in the process filtrates and favours the growth of microorganisms. Starch is therefore considered as a waste product, and usually ends up in the effluent of the process where it is disposed of in the treatment plant of the mill.

Starch is an interesting raw material though, which could have applications in materials or composites, or could be a source of glucose. Starch producers develop many applications from native starch: bioplastics, starch derivatives used as ingredients or additives for food and non-food applications, or the use of starch as a source of glucose (for its fermentation into alcohols and for the production of bioproducts such as sorbitol, lactic acid, succinic acid…)

The project aims at developing a biorefinery loop, integrated to the production of recycled paper or board, that would enable the extraction and reuse of starch.

The extraction of starch from recycled fibres during the pulping stage (i.e. the break-up of the recovered paper and boards by a mechanical treatment in water which produces a fibre suspension called “pulp”) is the key to this process, and different operating conditions are tested to favour starch dissolution without altering the quality of the cellulose fibres and keep them suitable for proper paper making purposes. Among the parameters to be tested at this step are the temperature, pH and time of pulping. The physico chemical properties of this “recycled starch” are then analysed in order to assess its quality (molecular mass distribution). A purification step may be necessary to eliminate the contaminants from the recycled starch solution.

From then on, two ways of valorisation are studied in the project: the depolymerisation of this recycled starch into glucose (chemical and biochemical processes are compared), and its potential use in composites chosen as an example of application. The mechanical properties of the materials obtained with recycled starch (through thermo-compression molding or ultrasonic-compression molding) are compared to those of the materials obtained with native starch in the same conditions.

Such a biorefinery loop for recycling starch from old corrugated containers (papers and boards) is a new concept, which has not been studied so far.

CONTACTS

- PI: Christine Chirat

- Co-PI: Jean-Francis Bloch

- Post-doc: Elsa Walger

PARTNERS

- LGP2

- 3SR

FUNDING

Tec21