Process improvement, characterisation and application of starch nanocrystal in flexible bioplastic and dispersion for food packaging and coating

Short term visitor's project

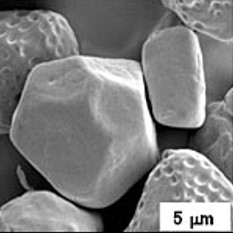

Due to the negative impact of synthetic plastics on the environment, growing areas for potential applications of bio-based products are in polymer biocomposites. Starch is among the most extensively studied renewable resources for such applications, in particular starch nanocrystals (SNCs) which are discrete crystalline platelets obtained by preferential acid hydrolysis of the amorphous amylose fraction of starch.

However, major drawbacks in SNCs production are still associated with the long duration of the acid hydrolysis treatment and its relatively low yield. Consequently, the molecular structure and functionality of obtained crystals can be affected. Various strategies including enzymatic and physical pre-treatment of starch before hydrolysis could be explored to improve the production process and application of SNCs. But very limited studies have been carried out on the use of modern food processing techniques coupled with starch debranching enzymes for the production of SNCs.

In this project, we intend to use high pressure homogenisation combined with starch debranching to improve the production process of SNCs for potential applications in flexible packaging and dispersions for food coating. Specifically, the effects of these pre-treatments on the morphological characteristic and the molecular structure of starch and SNCs end products will be investigated. Further, SNCs prepared using the most suitable pre-treatment conditions will be applied as reinforcement in flexible polymer biocomposites and characterised. For coating application, particle size distribution, surface charge and rheological properties of protein-based suspensions containing SNCs will be investigated. Non-conventional starch sources (e.g. Colocasia esculenta, commonly knowns as taro) and millet as alternative to conventional starches (e.g. maize and potato starches) will be explored in this project.

CONTACTS

- PI: Eric Oscar Amonsou (visitor)

- Co-PI: Alain Dufresne

PARTNERS

- Department of Biotechnology and Food Technology (Durban University of Technology, South Africa)

- LGP2

FUNDING

Tec21